Quality management

As experts in the production of products with sophisticated visual and technical requirements, we have been producing plastic injection moulded parts for food and non-food packaging, measuring and baby spoons, bioplastic products and products for the cosmetics industry for over 40 years.

At both of our production sites, quality and hygiene management is monitored regularly according to strict standards and evaluated by both independent auditors and customers.

Our management system is certified according to ISO 9001, BRC and ISO 13485.

We place particular emphasis on product safety and carry out a sophisticated hazard and risk analysis to evaluate all risks at each stage of production and develop countermeasures to manage or eliminate them.

We employ a highly skilled team to ensure that customer requirements are fully met. Our aim is to satisfy our customers with consistently high product quality. To this end, our employees receive regular, targeted product training sessions on the quality requirements of existing and new products.

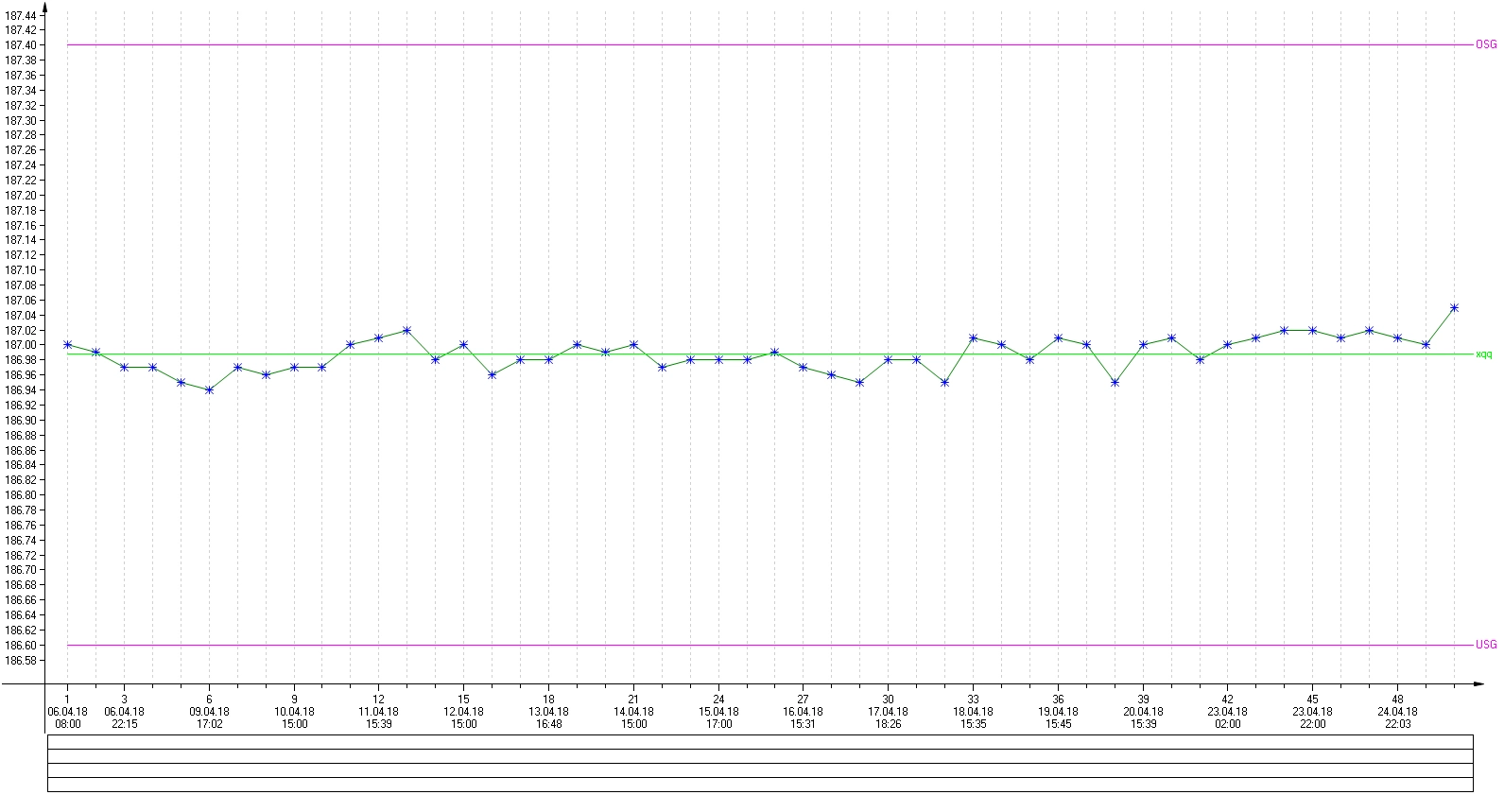

Our quality management system ensures the traceability of every product – from the material stage to the finished product and vice versa – so that you receive a batch number for each stage of production as part of a complete set of documentation.

All necessary analyses are carried out internally or by recognised and accredited laboratories to confirm the conformity of our products with the legal requirements.

Who’s perfect? Thanks to our efficient and meticulous quality management system, our complaint rate is constantly trending towards zero. Of course, we take each and every complaint seriously and endeavour to get to the bottom of it at the earliest opportunity. We do view see critical customer feedback as a criticism, but as a means to and an incentive for continuous improvement. Our goal is to reach a zero error rate.